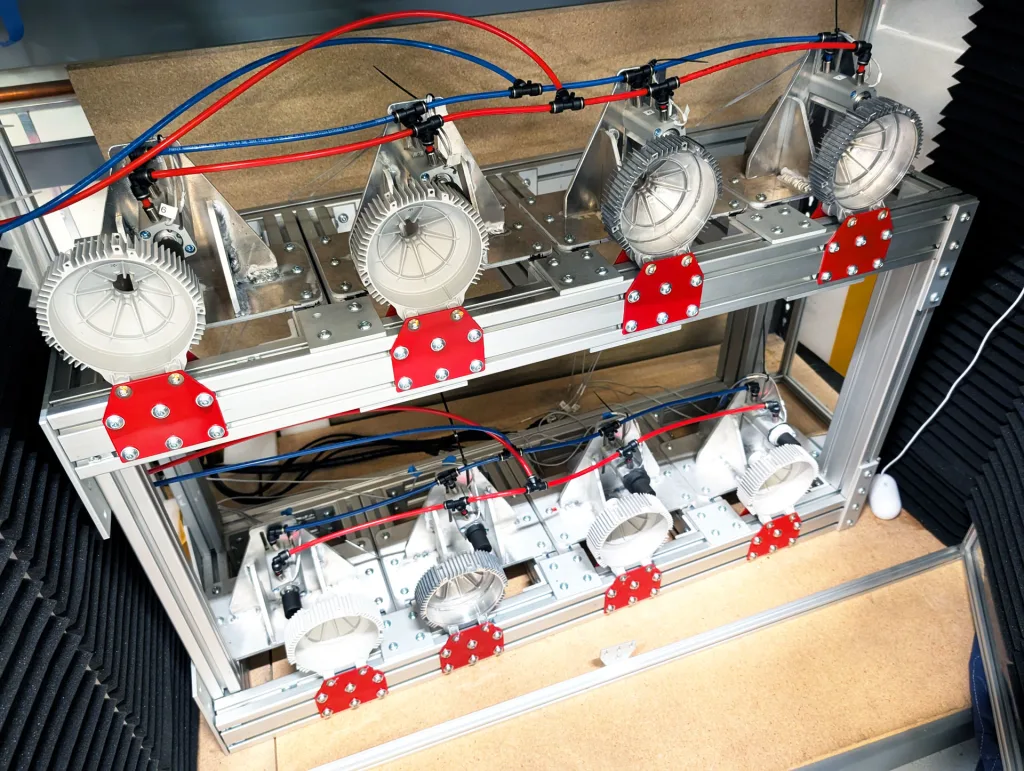

If you think drones are noisy during the flight, try to build and test them. During a visit last month to the Drone startup Zipline’s Factory in South San Francisco, California, industrial sound that was built in the corners of the facility – the roar of a wind tunnel, the rhythmic blow of a test installation simulation of the engine housing and other mechanical sounds in a symphony of Engineering.

Zipline has to subject its delivery drones to that kind of abuse because it has been building them in their own home since 2016 as a wiser than trust in outdated production. “Zipline has deliberately designed ourselves as a very vertically integrated company,” says Eric Watson, head of Systems Engineering.

The facility of the company, located just below the Jets flight path leaving San Francisco International Airport, combines warehouse, assembly and test room.

[Photo: Rob Pegoraro]

That, says Watson, lets the company repeat quickly and often. “We can quickly get the design engineer who built the thing to look at it,” he tells Fast Company. “And then we can update the test, update the drawing, whatever should happen.”

Zipline founded in 2014 (one of Fast Company’s picks for the most innovative companies of 2024) began to deliver medical supplies in Rwanda in 2016. Today it invoices itself as the largest commercial drone delivery service. The Live display on the site has more than 1.5 million deliveries so far; During a period of two hours on Saturday, that counter showed that a 48 was complete. (For comparison, Wing, the Drone-supplies service owned by the parent company Alphabet van Google, says it was made More than 450,000 residential deliveries.)

In the US, Zipline Walmart customers offers the option of drone deliveries in the Dallas-Fort Worth Area and Pea Ridge, Arkansas. (404 media discovered that Zipline had recently done The mayor of Pea Ridge provided talk points That then almost literally ran in a blog post on the company’s own site)

[Photo: Rob Pegoraro]

[Photo: Rob Pegoraro]

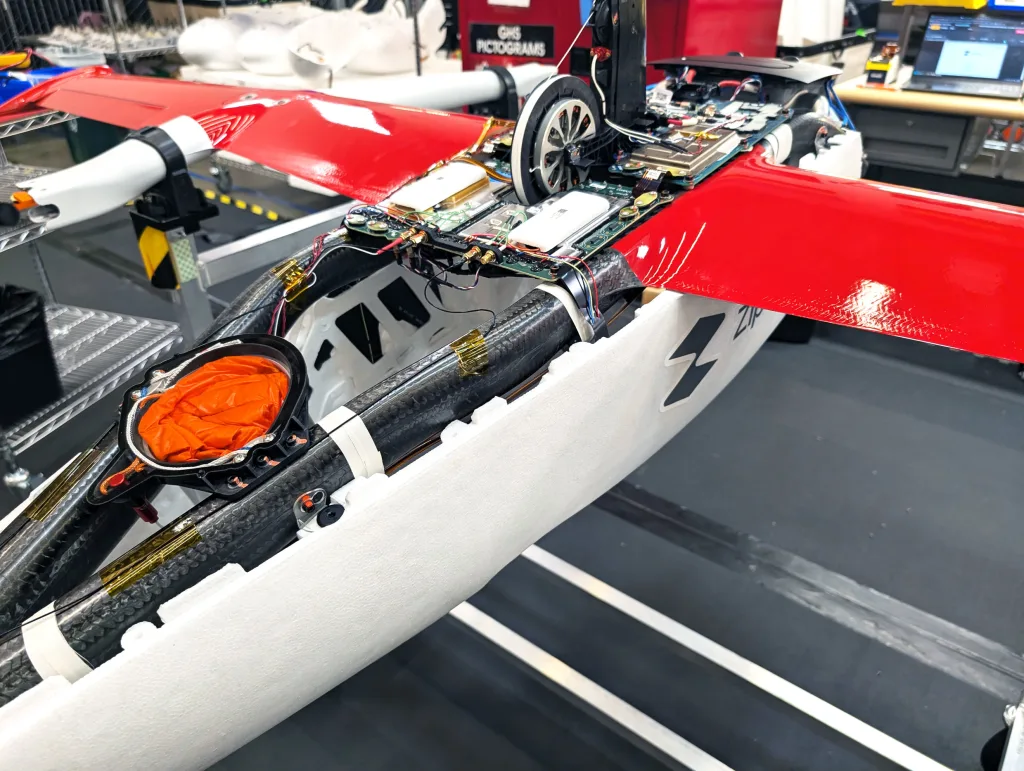

Zipline makes Two battery-electric drone designs. It describes its older platform 1 aircraft (or P1) as optimized for deliveries of a maximum of 4 pounds of ‘companies and government’ about distances up to around 60 miles from a zipline-exploited delivery hub. The newer platform 2 (P2) is built for home delivery of third -party sites, able to wear twice as much payloads, but with a service bead of only 10 miles. And where P1 drops its load through parachute, P2 rinses it under a 300 -feet winch in a freight compartment with its own fans to guide its descent to a precise place on the ground.

Watson described the approval of that winchitecture as a lesson that was learned about the difficulty to try to make a drone float directly about a delivery point in the wind: “We are now moving the plane against the wind.” That setup also keeps the Whir of the five combined rotors of a platform 2 300 feet distance from people on the ground, where the company says that is noise “Almost inaudible.”

P2 drones leave and return to the bottom of a landing dock, nesting a connector at the top of their hull in the source of that construction. During my visit, the activities of the factory focused on P2. Racks of the laughing light carbon fiber mass blows of that aircraft of wings and rotorn cells were in a corner of the building (I easily picked up one), spread test stations for components, and at a series of assembly files in the middle, employees performed such tasks as attaching a P2 drone’s two redundant system boards.

[Photo: Rob Pegoraro]

[Photo: Rob Pegoraro]

In the midst of signs, the dangers of testing hardware with rotating propeller blades and outside warned a closed door of a “risky test area with extremely loud noise levels and moving equipment”-moments of obstinacy and heat were.

The first platform 2 models required two to three days of work, but the company can now run away three a day. “We have made a lot of progress with our production of platform 2,” says Watson. “Later this year we should produce a plane every hour.”

However, Zipline does not manufacture every component itself. In addition to standardized parts such as fasteners, it has its own network of suppliers that build subsystems – for example the carbon fiber air frames – according to its specifications. “The way we have performed over time is to bring more things into the house,” says Watson.

[Photo: Rob Pegoraro]

[Photo: Rob Pegoraro]

Labels on some incoming boxes that originated in China or Vietnam remembered that this company is exposed to the rates of President Donald Trump – as much less than drone services, depending on consumer drones built in China.

“We have a global supply chain,” says Watson, adding that the vertical integration of Zipline “makes us a lot of flexibility” in suppliers.

The entire field of drone delivery has shown some of the same problems with a Te-Soonype as other technical boundaries. The highly published Amazon company in Drone delivery has made legitimate progress, but remains vaporware for almost all retail giant customers.

The business model also remains unclear. Private Zipline does not announce any income, costs per delivery or workforce, although the financing that Crunchbase sets up $ 821 million Gives a long runway to work with.

Zipline also has the advantage that it has guaranteed Authorization of the Federal Aviation Administration in September 2023 To operate drones beyond the visual facial line of an operator (BVLOS), with automatic broadcast from their location to other aircraft and high -limits.

In A report from January 2023The McKinsey consulting firm emphasized the importance of BVLOS operation when reducing drone delivery services per trip costs of what it estimated at $ 13.50 with one operator assigned to a drone up to $ 1.50 to $ 2 with one operator supervising 20 each time.

In October, a Subsequent McKinsey -Post emphasized a huge potential market – “$ 5 billion by 2035, with around 1.5 billion annual deliveries expected” – but warned that an ordered customer survey had unveiled a relatively low interest in drone delivery among American customers.

That study showed that 53% of American respondents said they were willing to switch to Drone delivery, but only 37% were willing to pay a premium. Both shares were observed the lowest in the six countries investigated: Brazil, China, Germany, India, Saudi -Aarabia and the US.

This suggests that although the hardware and software from drone delivery activities need further iteration, the sales pitch itself stays during the flight and may not land for a while.

#hightech #drone #factory #Zipline #delivery #innovation #flees